Phone Number

(+91) 8655358999

Industrial┬ĀInstrument Control Panel.┬ĀInstrumentation Control Panels┬Āare designed to monitor and┬Ācontrol┬Ālevels such as temperature, flow, current, and pressure from the field instruments that are connected to it. Instrumentation Control Panels are designed to monitor and control levels such as temperature, flow, current, and pressure from the field instruments that are connected to it. These panels are used in a wide variety of industries including: petrochemical, refineries, pipelines, pharmaceutical, water wastewater, and food processing.

Process equipment control panels can be designed to control several pieces of equipment to properly control the process. Their design should also include other important industrial design elements.

Chmeical Plants, Food Industries, Pharma Industries, Process Industries

These Control panles are specially designed for measuring and controlling flow. It is used for controlling the flow of valves.

Flow measurement in industries, Flow monitoring in different process industries, Specially designed for flow.

The analyzer panel is used to collect gas from the scavenging panel, cool the gas and send the gas to different analyzers (CO, CO2, H2 and O2) for analysis. It houses the logic required for both manual and automatic operation of the sampling system. It takes all the field inputs and processes. It gives outputs for operation of solenoids, pumps, etc. It displays information of all inputs and outputs through panel display unit. Through panel HMI interface clocking of system is possible in manual mode

Fully gas analysis Highly robust Also Multiple Gas Analysis Low Maintanance

Sample Conditioning Panels are designed to prepare a sample for analysis. This may include adjusting pressure, temperature, and flow rates. Different types of filtering may also be needed.

Acetylene samples Butane samples Ethylene samples Flue gas samples And many more

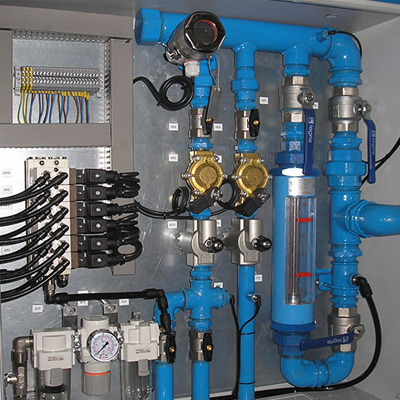

Pneumatic control cabinets allow a simple and practical control of all the cylinders and pneumatic actuators which conform a certain pneumatic installation powered by compressed air or other fluids. The cabinets incorporate inside and in one place all the pneumatic, electric and electronic components required to achieve the desired performance in each case: solenoid valves, filters, regulators, pressure gauges, flow control valves, electronic control systems, etc.

Food Material handling Product testing Compressor controls

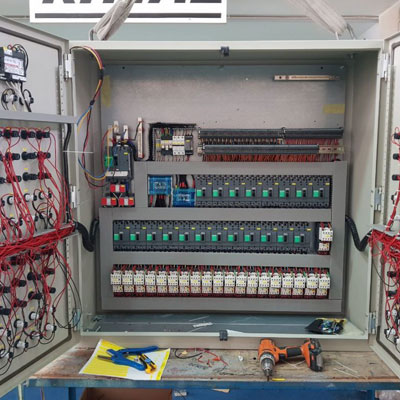

LT Panel is an electrical distribution board that receives power from generator or transformer and distributes the same to various electronic devices and distribution boards. Such panels are used in industries both for internal and external use and, therefore, they are quite rugged to withstand different climatic conditions. Our LT panels are designed to work with low electricity consumption that makes them cost effective. There are various uses of LT Control Panel as per the user requirement, the main being as Control Center or Feeder or Distribution Board.

There are various uses of LT Control Panel as per the user requirement, the main being as Control Center or Feeder or Distribution Board.

Medium to High capacity Manufacturing Industry Hospitals Educational Institutions Commercial Complexes

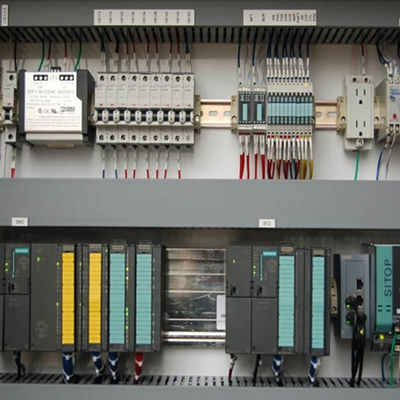

Programmable logic controller (PLC) control panels or also known as PLC Automation Panel are one of the most important and efficient kinds of control panels. Which are generally used in variety of electronic and electrical circuit fittings. PLC Control Panels we manufacture are highly capable of giving higher output at less power consumption. Integrated with solid PLC logic and flawless PLC hardware programming.

Process Industries Batch manufacturing Industries Continous Process Industries Chemical, Cement, Food and Pharma

The VFD Panel (Variable Frequency drive panel) also known as VFD Control Panel are designed to control the speed of electric motor and feed pump. They are widely used in drilling, pumping and other large machine applications. The VFD panels are widely used in extruder plants, rolling Mills, tube mills, paper mills, cable industry and CTL Lines. Adjustment of the speed of the motor is the application, which is required in all the process industries & machinery Mfg.'s. Variable Frequency drive is used as energy saving device for some of the machines to save power during no load or it is used as final control element of the closed loop control application where the speed of the motor is changed to control one parameter. Some of the application is provided with manual speed control of the motors. These are the open loop control applications.

Batch process manufacturing Continous process industries Controlling blowers and fans

Power control panels designed for industrial applications Quick and safe installation and start-up High-quality components (Eurotherm and Schneider Electric) Safety power contactor separated from the temperature control loop Optimized frame size for space saving Faster engineering time

Controlliing different electrical components in indsutries Rresidential as well as corporate buildings

The ABS Polycarbonate Enclosures are used where normal MS and SS Panels cannot be used. As a self-extinguishing material, polycarbonate requires no protective coating. ABS is another amorphous thermal plastic material with good physical properties and high resistance to chemical attack. It is an ideal cost effective material. ABS materials are less protective against UV rays if directly exposed. ABS/Polycarbonate enclosures are designed for indoor and outdoor use, but are small and light-weight, and provide a high tolerance to harsh environments. They come in multiple sizes and styles that fit small to mid-sized equipment.

Food Industries Pharma Industries Chemical Industries

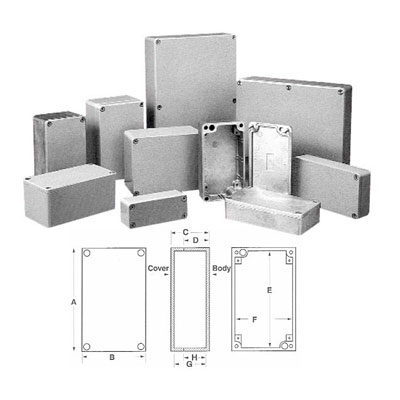

Aluminium enclosures are much lighter as compared to MS and SS Panels. They are light weight and durable.

Hazardous areas Process industry Machinery Transportation Port facilities Packing industry