Phone Number

(+91) 8655358999

Nuvision Instrumentation Solutions Pvt. Ltd. is a leading industrial automation company offering perfect process automation solution and industrial automation equipment. Since its inception as an outstanding industrial automation company, EPS Instrumentation Pvt. Ltd. is the imperative solution provider in the field of process and industrial automation. EPS Instrumentation Pvt. Ltd. excel in the field of Industrial Automation, Instrumentation & Controls and Electricals from over a decade & operates with a view to provide solutions throughout the plant.

We have a vast experience in executing Projects for Industrial Automation, Instrumentation & Electrical systems in all the major process plants like Power Generation, Refineries & Petro-Chemicals, Sugar, Steel, Fertilizers, Chemicals & many more industries throughout India & abroad too.

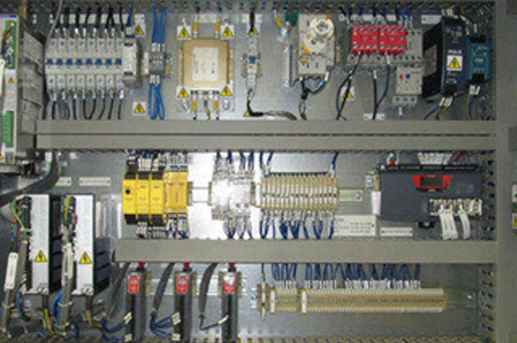

Nuvision Instrumentation is one of leading Automation service provider & system integrator, with expertise in the fields of Industrial Automation, Engineering Design, Integration and Commissioning of Intelligent MCC Panels. We are into Process & Factory Automation as well as Manufacturing of PLC, MCC, IMCC Panels. We also provide Engineering Services like software development, SCADA, HMI, FAT, SAT, undertake System Migration and Retrofitting of PLCs drives, HMI & SCADA system, MCC / PCC Panels and Numerical Multifunctional Relay & Energy Management Systems.

Instrumentation Engineering is defined as the art and science of measurement and control of process variables within a production, or manufacturing area. It is one of the brightest fields in engineering today. As an independent discipline, it deals with measurement, control and automation of processes.

Nuvision Instrumentation Solutions Pvt. Ltd. is a leading industrial automation company offering perfect process automation solution and industrial automation equipment. Since its inception as an outstanding industrial automation company, EPS Instrumentation Pvt. Ltd. is the imperative solution provider in the field of process and industrial automation. EPS Instrumentation Pvt. Ltd. excel in the field of Industrial Automation, Instrumentation & Controls and Electricals from over a decade & operates with a view to provide solutions throughout the plant.

We have a vast experience in executing Projects for Industrial Automation, Instrumentation & Electrical systems in all the major process plants like Power Generation, Refineries & Petro-Chemicals, Sugar, Steel, Fertilizers, Chemicals & many more industries throughout India & abroad too.

To technology in iron & steel industry is continuously improved to obtain the best possible performance. The improved plant performance gives rise to the higher quality improvement and lower cost, and simultaneously environmental friendly plant operation. The control systems and field instruments are working at the various processes of the iron and steel plant. The process of iron and steel plant is starting from Sinter plant, Coke oven etc, and the blast furnace, iron pre-treatment are following. The products are widely used at furnace control and utilities in important processes (such as continuous casting machine (CCM)) in down stream of iron / steel making process.

The Nuvision has rich experience in designing C&I systems for all types of industrial plants. Other than plant C&I, the department executes assignments like renovation / revamping of existing systems and also Communication and SCADA Projects. This division offers total engineering support starting with conceptual studies, micro-planning upto commissioning.

MCC stands for motor control center. It consists of feeders for motors and blowers. Feeders are designed according to the motor rating. In most of the MCCs, auto/manual provision will be there. With manual provision motors can be operated manually. In auto provision external signal is required to start the motor. The signal is given by the control panel. Indicators for the motor operation also will be present in control panel.

A motor control center (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. Motor control centers are in modern practice a factory assembly of several motor starters. A motor control center can include variable frequency drives, programmable controllers, and metering and may also be the electrical service entrance for the building.

Nuvision, "Commitment to service" has always been an integral part of our business philosophy. We firmly believe that customer satisfaction does not end with purchasing the right instrument but by providing technical & service support throughout the products lifecycle. To help you optimize the return on your investment and ensure greater satisfaction, we offer you services spanning from right selection of product to proper installation, asset maintenance, calibration services and training.

Our service engineers equipped with extensive onsite and classroom training are well qualified to understand your needs and deliver customized services. An extensive network of offices across India ensures fast and efficient service.

A control & relay panel is designed to provide to control the associated line or transformer through outdoor switchgear at various 11KV and 33KV zonal substations. The control & Relay panels are complete in themselves with all main and auxiliary relays, annunciation relay, fuses, links, switches, wiring, labels, terminal blocks, earthing terminals, base frame, foundation bolts, illumination, cable glands etc. These panels are used for the control & monitoring of electrical equipments such as transformers, generators and circuit breakers. Indoor Control panel for Outdoor VCB includes IDMT Numerical relay, Master Trip Relay, Trip circuit Supervision Relay, Indications & meters etc. These control & Relays panels are available in various combinations as single circuit or multi-circuit depending upon the customer requirements.

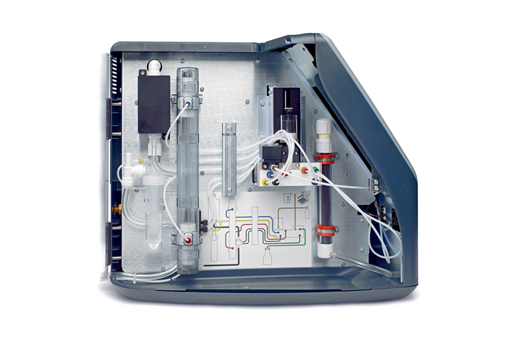

We specialise in multiparameter water testing equipment and highly precise water level and temperature loggers. Our water testing instruments are suitable for testing groundwater, surface water and waste water. They are made from rugged materials to withstand harsh environmental conditions and all types of water.

Analyzing air pollution is the first step toward preserving a clean atmospheric environment. Nuvision-FUJI developed the first infrared gas analyzer in Japan to use mass-flow sensors. Since then, we have supplied customers with various types of gas analyzers to support environmental preservation and control efforts. These efforts include measurements of atmospheric pollution and detection of low density of SOx and NOx, generated by incinerating facilities and boilers. FUJI's gas analyzer is commonly used to monitor the atmosphere to help maintain a cleaner natural environment.

Instrumentation Control Panels are designed to monitor and control levels such as temperature, flow, current, and pressure from the field instruments that are connected to it. These panels are used in a wide variety of industries including: petrochemical, refineries, pipelines, pharmaceutical, water wastewater, and food processing.

Nuvision has built Instrumentation Panels to meet unique customer specifications such as beacons, purge systems, and rain hoods. Instrumentation Panels find application in large scale process control of complex systems where quick response of the operator is essential to prevent failures. They are typically made for pharmaceuticals, chemical plants and refineries.